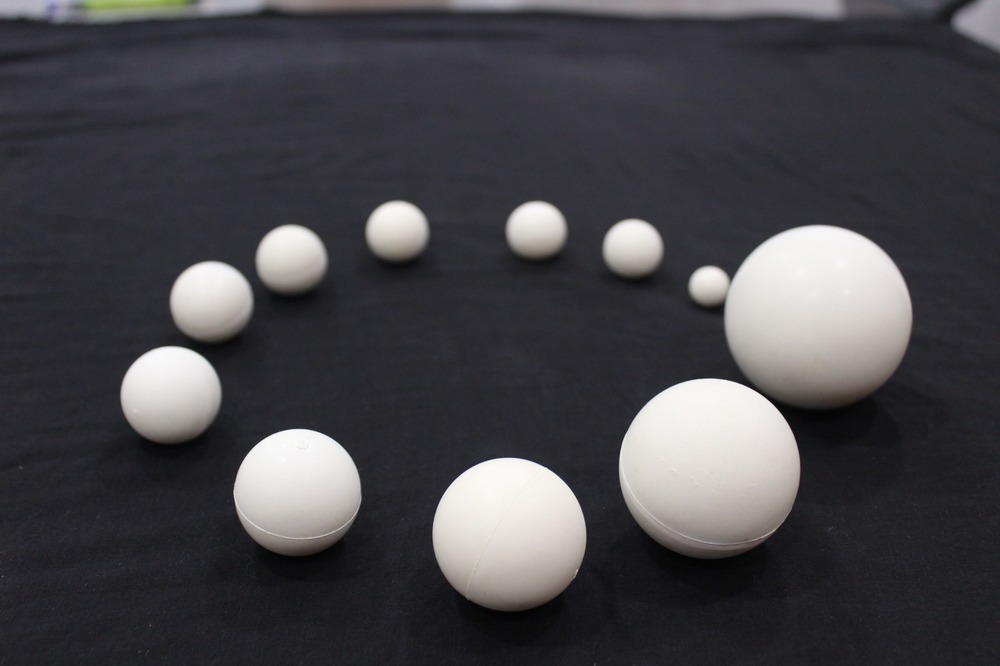

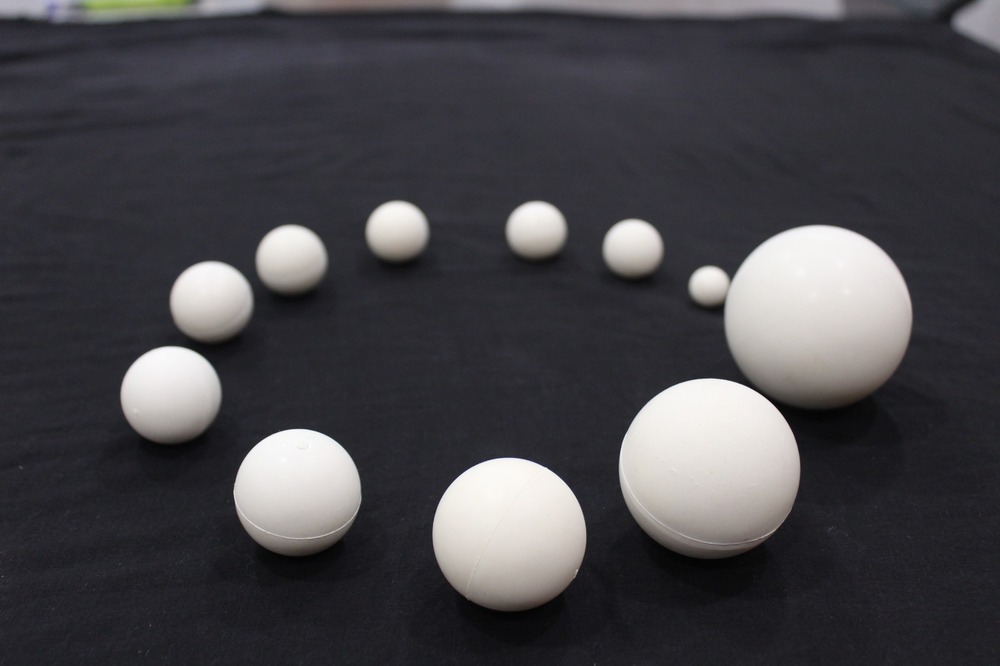

Nitrile Rubber Ball

Price 20 INR/ Piece

Nitrile Rubber Ball Specification

- Hardness

- 50-60

- Product Type

- Mining Balls

- Natural Rubber

- Nitrile Rubber

- Style

- Ball

- Feature

- High Durability and superb Tear strenght

- Material

- Rubber

- Thickness

- 16-63 Millimeter (mm)

- Color

- Black

- Usage & Applications

- Industrial or Machinery

- Surface Finish

- Smooth

- Rubber Type

- Natural Rubber

- Width

- 16-63 Millimeter (mm)

- Size

- 16mm to 63mm

Nitrile Rubber Ball Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 200000 Pieces Per Month

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Best Quality

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- Japan Food Regulations, EU , US FDA

About Nitrile Rubber Ball

"Rubber Nitrile Balls are designed for demanding applications in crushing, grinding, and the minerals industry. Engineered with high resistance to wear, oil, and abrasion, these balls deliver reliable performance in powder-making and material processing operations. Their toughness and elasticity ensure efficient grinding, extended service life, and consistent results in heavy-duty industrial environments.Exceptional Durability and Versatility

Engineered with high-performance nitrile rubber, these balls are designed to withstand tough industrial environments. Their hardness rating of 50-60 and tear-resistant nature make them suitable for applications such as sealing, damping, and mechanical isolation. Their adaptability ensures reliable function across diverse settings, from machinery to hydraulic systems.

Comprehensive Size Range for Multiple Applications

Offering a size range from 16mm to 63mm in both width and thickness, these nitrile rubber balls cater to various operational requirements. Their precise manufacturing assures a consistent smooth surface, optimizing their effectiveness in machinery, pumps, and valves where a flawless surface and material reliability are critical for system integrity.

FAQs of Nitrile Rubber Ball:

Q: How is the nitrile rubber ball typically used in industrial or machinery applications?

A: Nitrile rubber balls are primarily utilized for sealing, cushioning, and flow regulation in industrial and machinery setups. Their high durability and tear strength allow them to perform reliably in pumps, check valves, and hydraulic systems, ensuring efficient operation and reduced wear.Q: What distinguishes nitrile rubber from other types of rubber for these balls?

A: Nitrile rubber is chosen for its exceptional resistance to oils, chemicals, and abrasion, making it superior for applications involving exposure to harsh substances. This ensures the balls longevity and robustness compared to natural rubber variants.Q: When should I select a nitrile rubber ball with a hardness of 50-60?

A: A nitrile rubber ball with 50-60 hardness is ideal when you require a balance between flexibility and strength. This range offers sufficient rigidity to withstand pressure while maintaining enough pliability for sealing and cushioning tasks.Q: Where can these nitrile rubber balls be sourced from?

A: As manufacturer, exporter, and supplier based in India, these nitrile rubber balls can be ordered directly for domestic or international delivery, ensuring you receive consistent quality and prompt service.Q: What is the manufacturing process for these nitrile rubber balls?

A: These balls are produced using a molding process, where high-grade nitrile rubber is shaped and vulcanized to achieve the desired size, thickness, and smooth surface finish, resulting in uniform quality and reliable mechanical properties.Q: How does the smooth surface finish benefit industrial applications?

A: A smooth surface ensures minimal friction and wear during use, enhancing the efficiency of machinery and reducing maintenance needs. It also supports effective sealing in dynamic and static applications, contributing to system longevity.Q: What are the main advantages of choosing this nitrile rubber ball?

A: Selecting this nitrile rubber ball provides benefits such as high resistance to wear and tear, compatibility with various industrial fluids, wide size options, and assurance of durability, making it a practical choice for demanding engineering environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SIEVE CLEANING BALL Category

Rubber Ball 32mm For Cleaning and De Stonning in Seed Mills

Price 13.40 INR / Piece

Minimum Order Quantity : 100 Pieces

Natural Rubber : Natural Rubber

Color : White

Material : Rubber

Feature : High Durability and High Bounce Ball

Rubber Ball 35mm For Cleaning and De Stonning in Seed Mills

Price 18.70 INR / Piece

Minimum Order Quantity : 100 Pieces

Natural Rubber : Natural Rubber

Color : White

Material : Food Grade Rubber

Feature : High Durability and High Bounce Ball

40mm Sieve Cleaning Rubber Ball For Flour, Rice, Grain and Seed Mills

Price 25.50 INR / Piece

Minimum Order Quantity : 100 Pieces

Natural Rubber : Natural Rubber

Color : White

Material : Rubber

Feature : High Durability and superb Tear strenght

White Rubber Ball For Sieve Clean in Flour mill

Price 10 INR / Piece

Minimum Order Quantity : 100 Pieces

Natural Rubber : Natural Rubber

Color : White

Material : Rubber

Feature : High Durability and High Bounce Ball

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese